For LNG FGSS there is no “one size fits all”.

For this reason our LNG FGSS are custom built based on your specific design requirements and wishes. By following this route we make sure that the design is the perfect fit for your purpose while keeping the CAPEX of the system within your available financial budget. With the current status of the IMO’s Net Zero Framework and FuelEU initiatives LNG and / or Bio LNG continue to remain a valuable option especially for ships > 5000GT when looking at the TCO.

To give you a general idea on the design possibilities we can suggest a few design options:

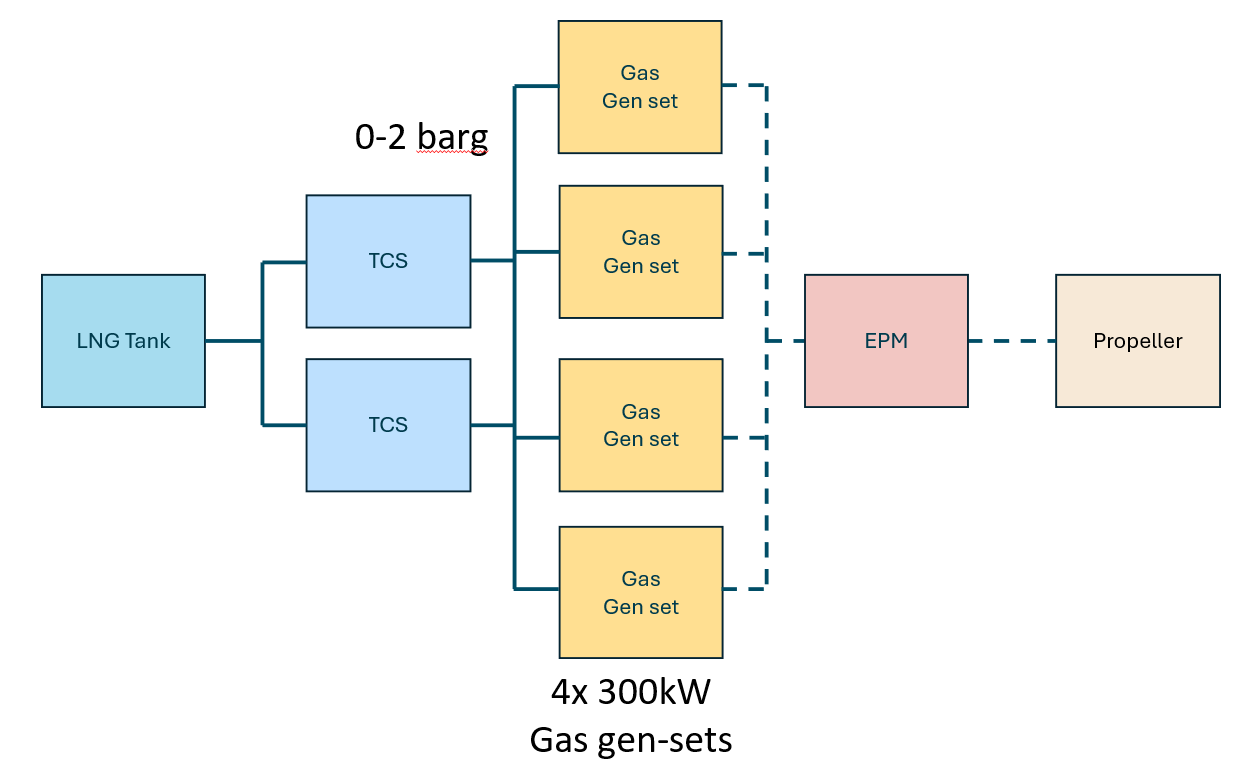

Design 1 Inland-barge with hybrid propulsion

For this design we assume an inland barge with around 1200kW of propulsion power. The LNG FGSS can consist of one type C LNG tank installed below deck with two tank connection spaces giving the system redundancy for single fuel systems. Propulsion can be provided by one or two thrusters or one ore two electric propulsion motors (EPM´s). Electricity is provided by four gas fueled generator sets of around 300 kW each. The pressure inside of the LNG fuel tank can remain low because the gas generator sets require a lower pressure than DF engines. The hybrid propulsion gives the possibility to change fuels in case another fuel should become more cost effective in the future.

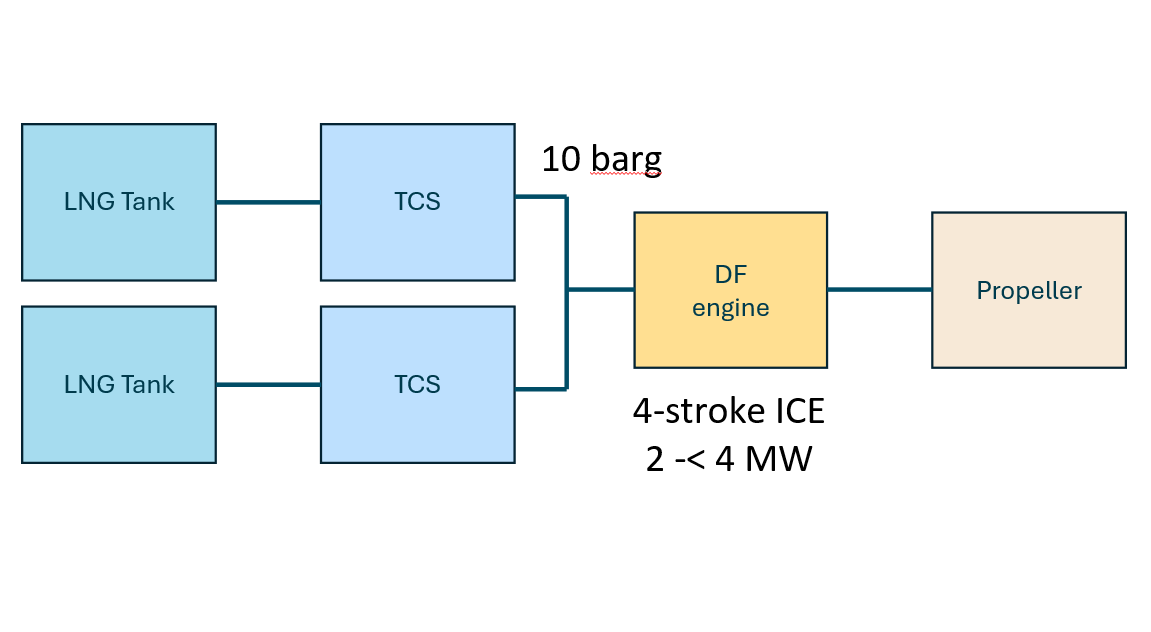

Design 2 Short-sea vessel

For a short sea vessel we assume a general cargo vessel < 5000GT. Propulsion power will be somewhere between 2000 kW and 4000 kW with an endurance of around 4000 nm. For this design we can propose two LNG tanks with two tank connection spaces which can be installed either above or below deck. Propulsion can be either hybrid electric with dual fuel generator sets or direct propulsion with a dual fuel propulsion engine. We can work with a PBU or LNG FGSS pumps to provide the 10 barg of pressure required.

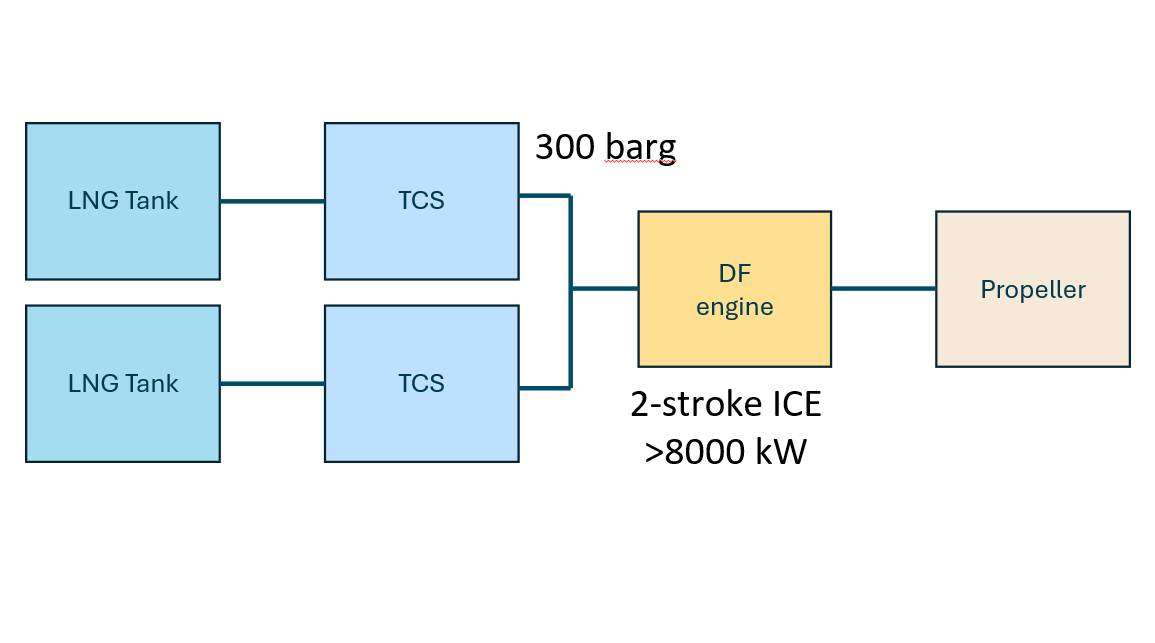

Design 3 Deep sea vessel

For a deep sea vessel >5000GT with >8000 kW of propulsion power you probably will require two LNG tanks with a high pressure pump of around 300 barg to provide direct injection to the engine. The high pressure pumps need to be installed as close to the main-engines as possible. By using fuel pumps to feed the fuel to the engines the pressure in the LNG tanks can be kept low which results in a longer holding time.

Clearly, there is no “one size fits all” when it comes to the design of an LNG GFSS. We would love to hear from you if you like one of the proposed designs or have an even better idea. If so, leave us a comment in the contact form below and we will reply to your message ASAP.