Two concepts for a methanol fuel system

In response to the increasing demand for cleaner ships, we have developed two concepts for a methanol fuel supply skid. Engine suppliers have developed different concepts to use methanol as a marine fuel, we can design and build the low-flashpoint fuel supply system (LFSS) for these engines.

The different concepts that engine suppliers apply are fumigation in the engine air intake and direct cylinder injection. Mixing (blending) of methanol and gas oil is not possible due to the low solubility in gas oil.

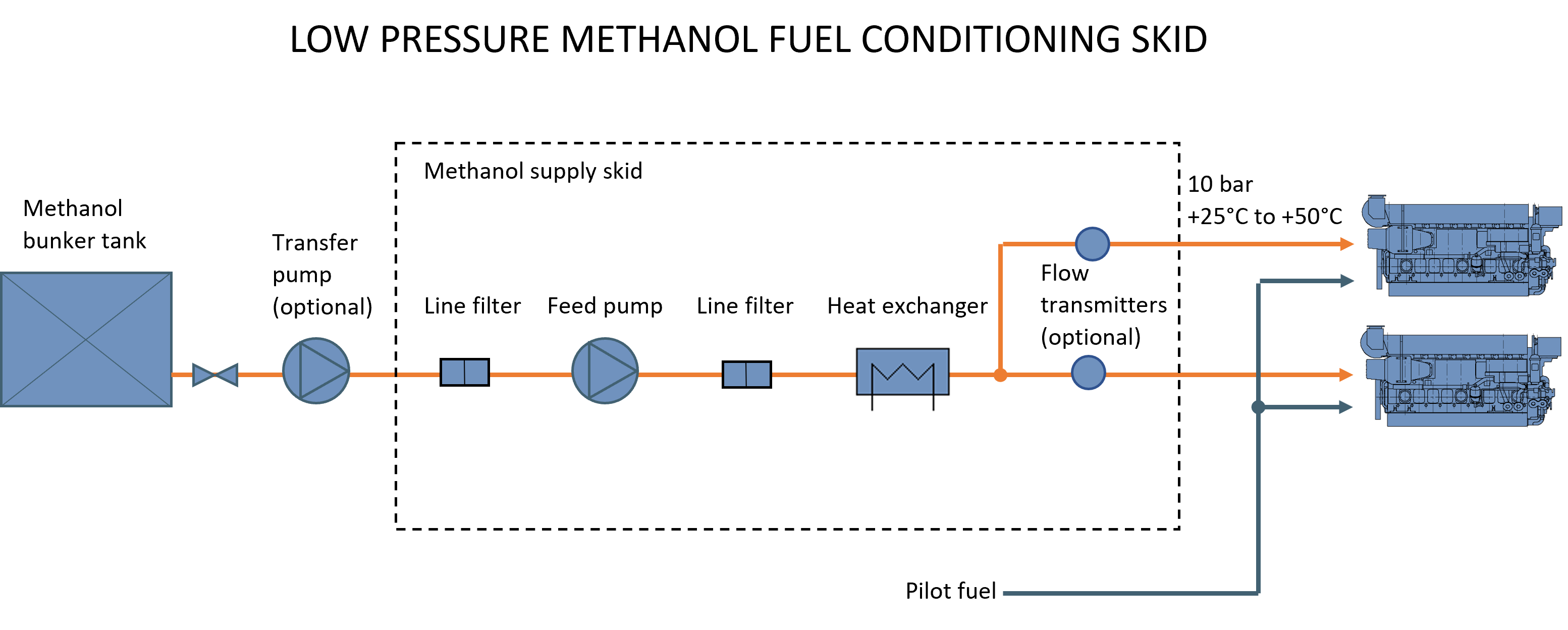

Low Pressure Methanol supply skid

Low pressure methanol supply is used by MAN, ABC and MTU, among others. Methanol is supplied to the engine at a pressure of approximately 10 to 25 barg and a temperature between 25 and 50 degrees Celsius. For this application we have developed a low pressure methanol skid. The methanol transfer pump can optionally be mounted on the skid depending on the position of the skid and the methanol bunker tank.

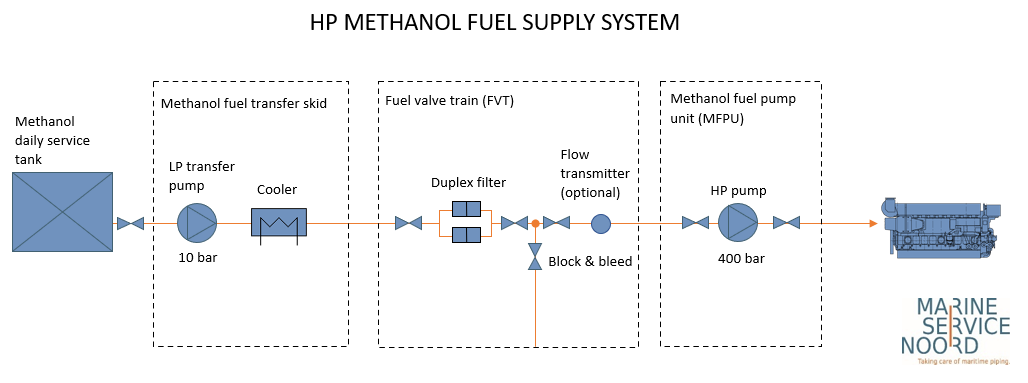

High Pressure Methanol supply skid

High-pressure methanol injection is used by, Wartsila, among others. Methanol is (optionally mixed with water) supplied to the engine under a pressure of approximately 400 bar. The skid is composed of a low pressure methanol transfer pump, a water dosing unit, a mixing tank and a high-pressure methanol pump.

Source:Wartsila

As a member of the Green Maritime Methanol consortium, we contributed to the case study to convert the Wagenborg cargo vessel MV Eemsborg to methanol as marine fuel. Click on the link below for more information.