Hydrogen storage on a ship can either be achieved by storing it as a liquefied gas at very low temperature (-253°C) and with a slight overpressure or by storing it as a compressed gas at high pressure (typically 250–500 bar).

PRESSURIZED HYDROGEN STORAGE

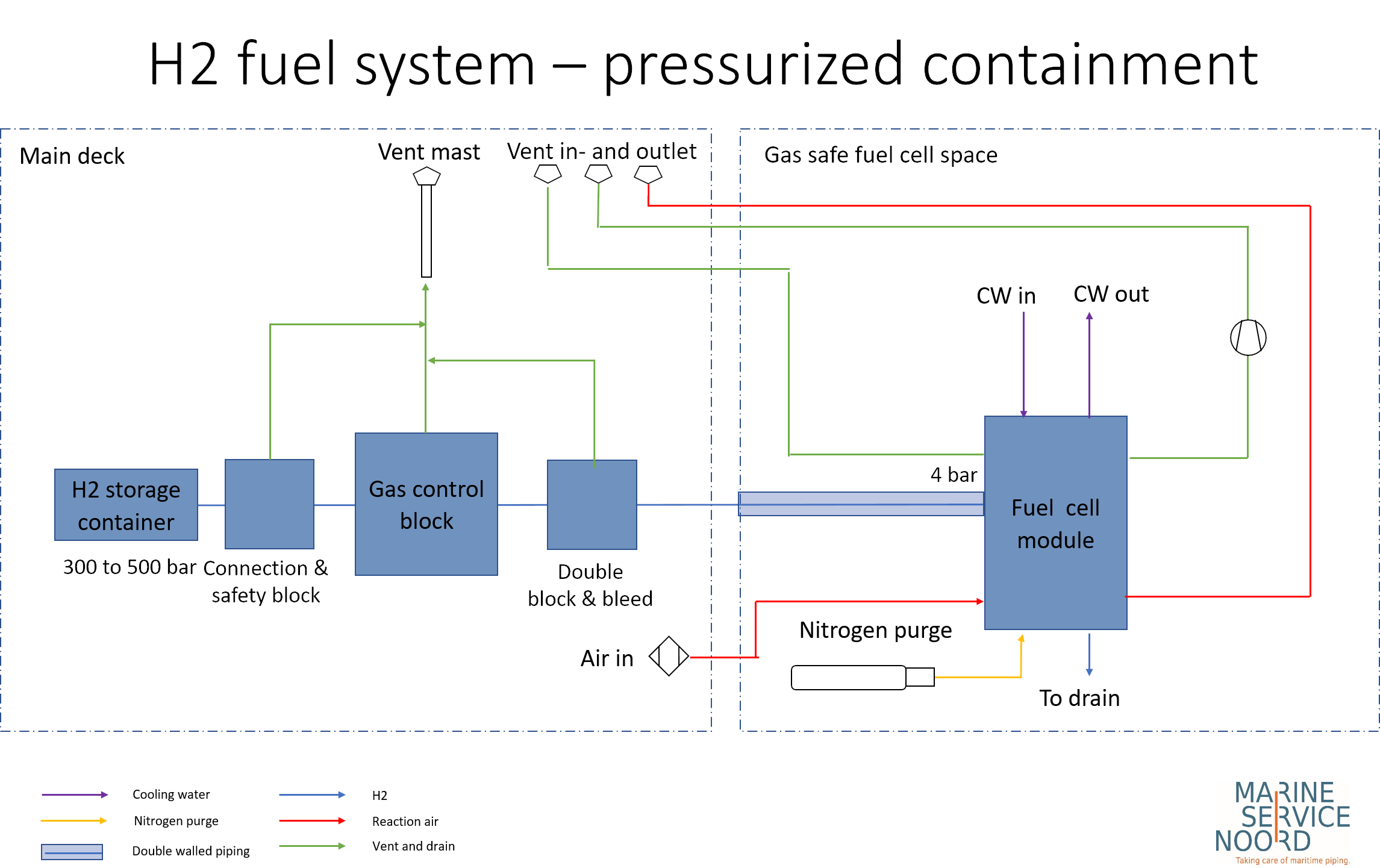

Hydrogen can be used as fuel for ships. Due to it's higher volumetric energy density it is specifically suitable for ships with lower power requirements in combination with relative short operational time (<1500kW, <2000nm), For these ships pressurized storage is likely to be the best solution. We will supply the hydrogen storage container(s), connection and safety distribution blocks, gas control blocks, double block and bleed valve blocks, valves, instrumentation and pipe lines. We can also design and supply double walled pipes for use in gas safe machinery spaces (fuel cell spaces).

It is paramount that our system design corresponds to your specific wishes, the requirements of the IMO Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF) and the regulations of the classification society of your choice. The IGF and class regulations for pressurized hydrogen storage do not yet fully accommodate this new technology yet. However, by following the risk based design process, there is no need to wait, we can assist you in obtaining an Acceptance in Principle (AiP) from the classification society of your choice.

A pressurized H2 fuel system contains the following elements:

- 10 tot 45ft Hydrogen storage container(s) with 300, 350 of 500 bar pressure

- Light weight type 4 hydrogen storage cylinders

- Connection- and safety supply blocks

- Gas regulating blocks

- Double block and bleed valve blocks

- High- and low pressure hydrogen pipe lines

- Vent and drain pipe lines

- Vent mast

- Cooling water pipe lines

- Double walled pipe lines in gas safe machinery spaces

- ESD system

- Alarm monitoring and process control system

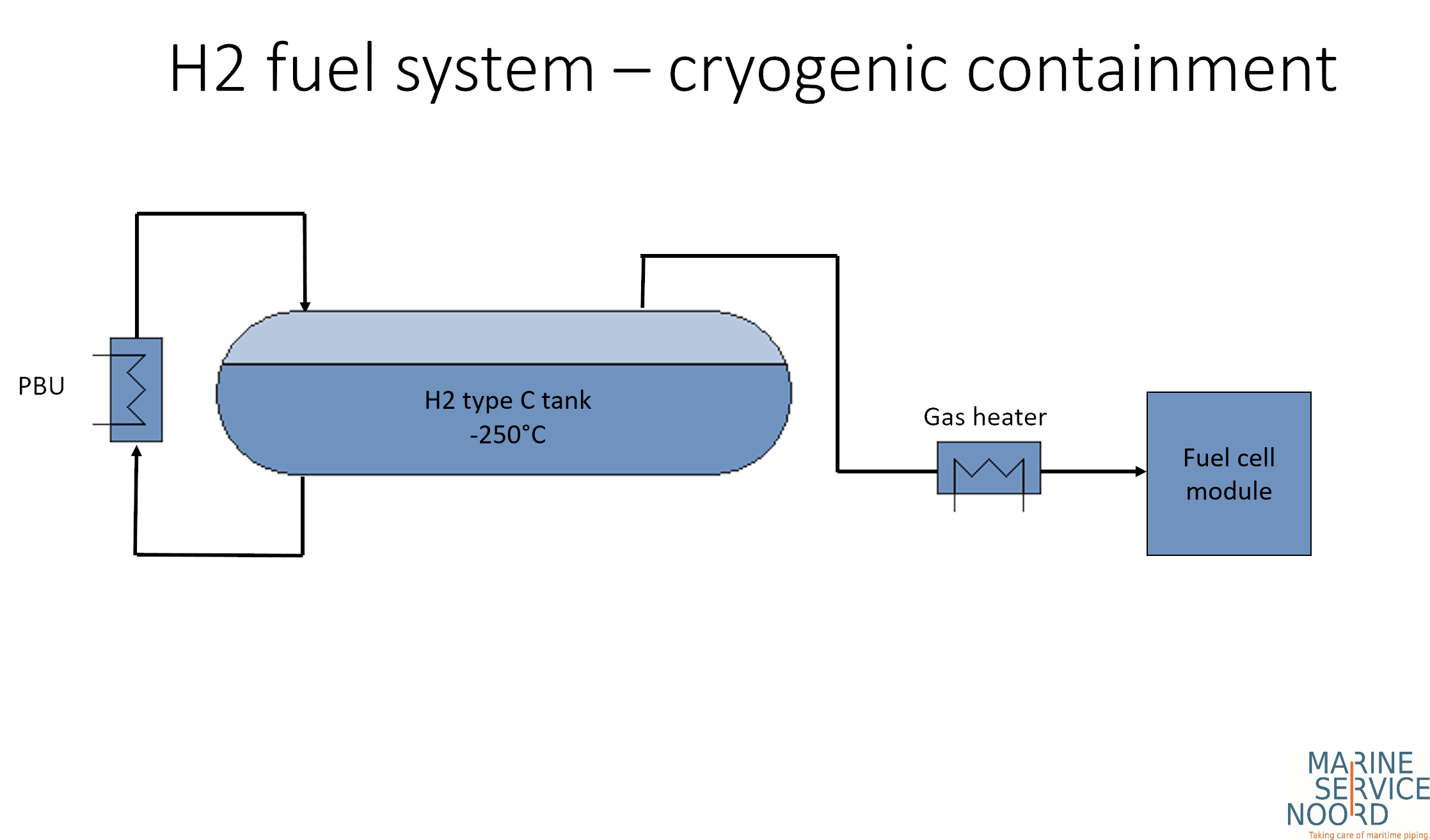

CRYOGENIC HYDROGEN STORAGE

For greater power requirements in combination with longer operational time, designing a system with cryogenic storage is an option. In such a system, a type C tank stores the hydrogen and a pressure build up heat exchanger maintains the tank at the desired pressure. Feeding hydrogen to the consumers reduces the pressure in the tank. A gas heater (shell and tube heat exchanger) heats the hydrogen gas to the correct temperature before it passes to the fuel cell. Insofar as possible, all the equipment, valves and instrumentation are assembled in a gastight tank connection space (TCS) which is then welded to the tank.

A H2 fuel system with cryogenic storage contains the following elements:

- Hydrogen storage in a type C tank

- Tank connection space (TCS)

- Pressure build up heat exchanger

- Gas heater

- Hydrogen pipe lines

- Vent and drain pipe lines

- Vent mast

- Double walled pipe lines for use in gas safe machinery spaces

- ESD system

- Alarm monitoring and process control system

To find out how much hydrogen you need for your next project check out the link below.

Would you like to know more about hydrogen storage options for your hydrogen powered ship? We are happy to inform you of all the options. Contact us to set up a no-obligation consultation or complete the contact form below to receive our free brochure on H2 fuel systems.