How do I design my system for alternative fuels like ammonia, methanol, and hydrogen?

The maritime sector is on the brink of a major energy transition. Sustainable, carbon-free fuels such as ammonia, methanol, and hydrogen are increasingly seen as viable alternatives to meet the emission targets set out in MEPC 83. But the use of these new fuels presents shipowners, shipyards, and designers with a fundamental question:

How do I design a safe, approved, and future-proof ship fuel system that also fits within my financial budget?

At Marine Service Noord, we closely follow the regulatory and technical developments in this field. As recently described in this whitepaper by DNV, we’ve outlined the most important design steps you should take in to get to the best possible system design in an efficient manner.

No Standard IMO Regulations? Use the ADA Process

Since regulations for ammonia, methanol, and hydrogen are not yet fully developed, approval must go through the IMO’s Alternative Design Approval (ADA) process. This means you must demonstrate to a classification society that your design is safe and sound.

The ADA process consists of seven steps:

- Follow the applicable class rules and use them as a foundation for ADA.

- Consult early with flag administrations and class to align expectations and avoid delays.

- Use the extensive and growing body of knowledge from previous projects to anticipate which risk studies and documentation may be needed.

- Integrate comprehensive safety measures in the design, especially for leak prevention, gas dispersion, and crew protection.

- Update Safety Management Systems (SMS) and develop fuel-specific operational procedures.

- Invest in training programs until formal STCW courses are available.

- Coordinate safe bunkering protocols and obtain the necessary port approvals.

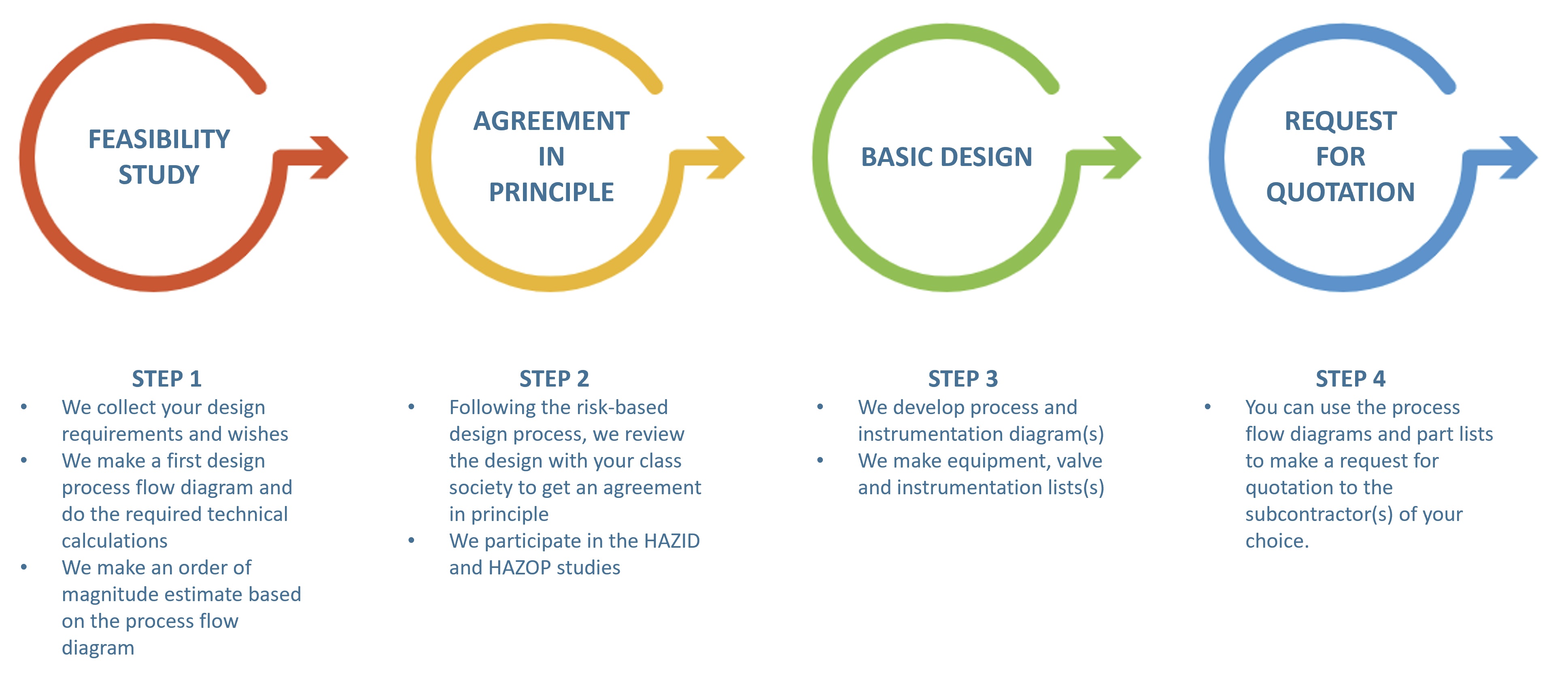

System design and approval in 4 practical steps

Planning to design your ship or fuel system for ammonia or hydrogen? We recommend following these four steps:

Design challenges by fuel type

Hydrogen

- Extremely flammable and explosive.

- Stored in high-pressure tanks (up to 700 bar) or cryogenic tanks (−253°C).

- Focus areas: leak prevention, gas dispersion, ignition protection, and freeze prevention.

Ammonia

- Toxic and corrosive; hazardous upon inhalation or skin contact.

- Safety focus: ventilation, safe bunkering, leak detection, and crew protection (such as "safe havens").

Methanol

- Easy to handle and store – now available in over 100 ports worldwide.

- The volumetric energy density is lower than gas oil but higher than hydrogen and ammonia. So, you'll need a smaller tank compared to other alternative fuels.

What does this mean for your project?

When designing a system for alternative fuels, you must consider technical risks, regulations, and operational safety from the concept phase. Collaboration with classification societies, flag states, and experienced maritime partners is essential.

Marine Service Noord supports you from day one: from technical design and risk management to construction and commissioning. Whether you're working on a newbuild or considering a retrofit for LNG, methanol, ammonia or hydrogen – we guide you toward a safe, approved, and future-proof result.

Do you want to know more? Contact our team for a non-binding consultation about your project or design challenge. We're happy to support you with knowledge, experience, and practical solutions.