HOW WE WORK

Our team has been fortunate enough to work on many wonderful projects. During the implementation, we ensure the delivery of an optimal product. We check the work at every stage in order to easily make adjustments if required. To ensure the quality of our work, we adhere to standard procedures and strict quality standards. Each new project is assigned its own project manager, who monitors the quality, planning and costs and who acts as your first point of contact as a customer.

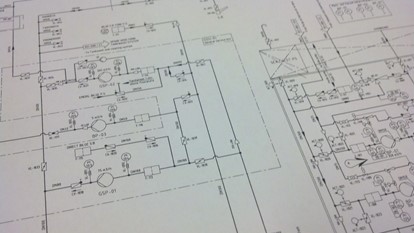

DESIGN PHASE

An important step in our routine is the project’s engineering design. During this phase, we work in close collaboration with our customer and the classification society.

The design phase includes the following activities:

- Definition of design requirements and customer needs

- Design of piping systems

- Creation of process and instrumentation diagrams

- Performance of all required calculations

- Drawing up bills of materials for equipment, valves and instrumentation

- Obtaining Classification Society approval of diagrams and calculations

- Preparation of technical and instruction manuals

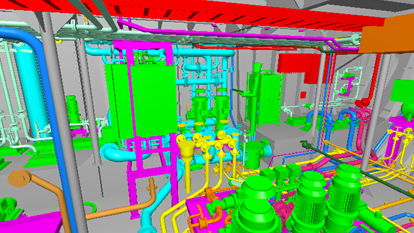

ATTENTION TO DETAIL

In the detail engineering phase, we make use of 3D drawing program Nupas Cadmatic© and Siemens NX©. As a customer, this offers you a virtual look at the engine room design before we proceed to the production phase. No detail escapes our attention.

The detail engineering phase includes the following activities:

- Routing of large pipes (piping) and smaller pipes (tubing)

- Division of pipelines into work packages (jobs)

- Creation of equipment foundation drawings

- Creation of arrangement drawings (AXO views)

- Creation of isometric drawings (ISOs)

- Generation of material take offs (MTOs)