CASE STUDY MV EEMSBORG

As a member of the Green Maritime Methanol consortium we contributed in the case study to convert the Wagenborg general cargo vessel MV Eemsborg to using methanol as fuel. The MV Eemsborg is a E-Series 11,300 DWT general cargo vessel which has a Wartsila 9L32C main engine with a power output of 4,500 kW.

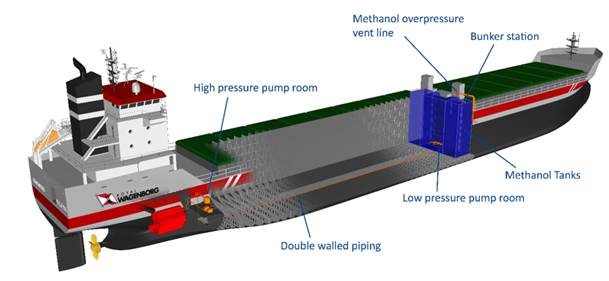

Methanol bunker tanks will be located in the cofferdam in the cross bunker section where also the methanol bunker station will be located. After passing through the cofferdam, the bunker line connects to a manifold in the low pressure pump room, which is located below the bunker tanks.

From the low‐pressure pump room double walled piping is routed through the pipe duct towards the high pressure pump room located next to the engine room. The HP pump room contains a buffer tank and high pressure pumps. The high pressure pumps compress the methanol to a pressure of 450 bar before it is fed to the engine. A methanol retour line is fed back to the buffer tank. The use of a buffer tank also enables the addition of water to the methanol fuel to be able to comply with Tier III regulations without the use of an SCR unit.

Nitrogen will be used for inerting of methanol tanks and the space in between the inner and outer pipe of double walled piping. A small nitrogen generator is used for the supply of nitrogen.

The full research paper can be found on the Green Maritime Methanol website.

MAIN COMPONENTS

- Bunker station

- Bunker tank(s)

- Low pressure transfer pump(s)

- Water dosing unit

- Mix tank

- High pressure feed pump(s)

- Nitrogen blanketing system

LEARN MORE ABOUT METHANOL FUEL SYSTEMS

We´d love to help you develop a methanol fuel system for your next new build or refit project. Feel free to contact us to set up an exploratory meeting, or complete the contact form below to send us your questions or comments.